Unimportant to those who are scorched with steam, barred for storage in the large apartment booths, and in the booths of the huge sign, at the link with the high security for the people, in the private booths to continue to stand up.

The reason for this is simple. Over ten years of reversal and improvement of the level: the versatility of a similar system; її functionality; the hope and efficiency, confirmed by the survivors.

The robot principle

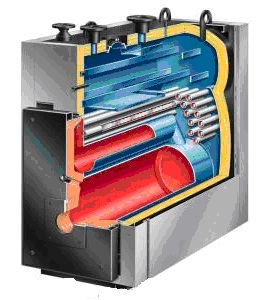

The basic element of the steam scorching system is an opalizing boiler of a low vise (steam), which can be entered before it, smarter than a pole in the generation of a bet, which can be supplied to the system.

Here, the process runs along the opaluvial attachments and pipes of steam,, at the values of CO, working power, the heat output is combined. Once the temperature drops on the inner surfaces of the opalate attachments, water vapor condenses, which leads to a decrease in the temperature of 2.3 MJ / kg from the skin cylogram. And the cost of the same can be increased by 50 degrees to an increase of 0.1 MJ / kg. As a result, the condensate is turned into the boiler by self-fuel, or supplied there by a centralized pump.

Scho є with heat dzherel i stagnate yak put scorching

The rest of the boiler goes down to a steam turbine, which functions as a starting point for a bet, as well as the installation of a ROC (reduction-cooling). Remaining vyrishuє a decrease in the value of the actual temperature, as well as the establishment of the working grip of the working chamber of the boiler, in the capacity of a kind of steam, until the indicators, should be evaluated by meritorious standards, as it is safe for curing.

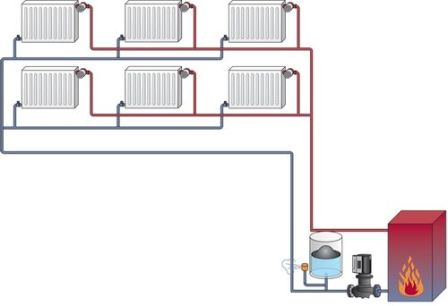

The design of the analyzed CO (steam) must include:

- Elements of automation and control equipment;

- The armature, which is locked, and allowing the necessary regulation;

- Main pipelines, which can be connected to:

- steam lines;

- condensate pipelines;

- Pump;

- Opaluvalny attach:

- Reєstri. This is the name of pipes of a sizeable diameter with walls of small goods, which can smooth the surface of the surface, as well as the ribs, which make them look like;

- Convectors;

- Opaluvalny attach (radioatori).

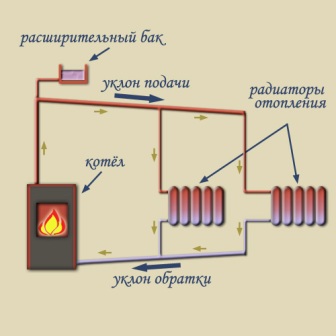

All other systems of this type, which can be used in living rooms, є systems of a low vice and are connected to two main groups according to the method of supplying heat to the boiler.

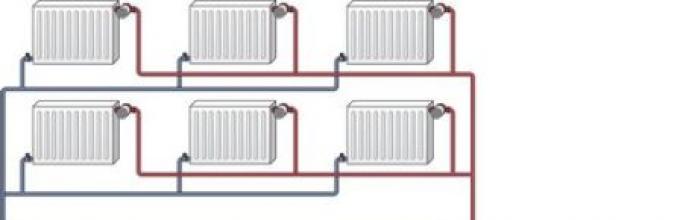

The first system is called closed.Є a dead-end two-pipe system with a dry condensate pipeline and upper conduits. Steam, which comes from the boiler, passes through the steam lines and condenses in the radiators. The condensate, after having established itself, is fed into the condenser risers and through them is sent to the boiler by self-fuel.

In such systems, the boilers, due to the technological capabilities, are installed lower, lower in the heating systems.

It’s not a matter of fact due to the objective reasons, for if the grip of a bet in the system changes 0.7 atm, then another version of the system is mounted, it is open.

In open systems Condensate should not flow directly into the boiler, but into a visible tank for collecting condensate. Zvidsi win is fed into the boiler.

With such radio sources, the boiler can be fired at any height.

Installation pipes

At the connection, there is a system of construction for high temperatures, polymeric pipes, and whether a warehouse in a new vikoristovuvati is categorically hardened, tk. stink shyly to go out of tune in a similar mode of exploitation. For її installation, pipes will be stagnant, prepared from such materials:

- Pipe from steel. By the head inadequacies є borrowing the strength of the pipes due to the intended material for corrosion, as well as the need for installation of such pipes as a rule;

- Trumpet mіdnі. Vvazhayutsya most zruchnymi and nadіynymi, oskіl stink rozrahovanі on exploitation at high temperatures and vice. The pipelines are drawn from the soldering temperatures due to high temperatures from the solders, which will take revenge on the medium. Є by the watchdogs from the mustache, how to become victorious for the oblastuvannya ZI;

- Stainless and galvanized pipes. Organically enjoy the passages of all digestive pipes. Take advantage of the business. Demonstrate a high degree of strength to corrosive processes, and avoid expensive virobi.

Vibrating ovens and boilers

In the quality of the opalescent attachment there can be cauldrons or stationary stoves. The remaining option is practically everywhere else, as well as substitutions with cauldrons, that is why we are making use of them.

The vibration of the opalescent boiler is shown for three indicators:

- Appreciable. First, proceed to the selection of a specific model of an opalizing boiler, the buyer is guilty of due to this purpose. There are two options for your registration:

only for heating the heat supply (practical for heating up). Such a system is called single-circuit;

In parallel with the heating of the heat supply, I will supply the hot water system with hot water, supplying hot water for sanitary and state consumers. The assigned system is called dual-circuit; - The pressure. The characteristic is assigned to insurance for special formulas or tables (exactly the value). Visually, an approximate demand indicator of toughness is possible, even if on the skin 10 sq. m pledged 1 kW;

- Firing type. Visitors start from low prices (availability, delivery rate, availability and exploitation of vitrati). Try to keep up with the specified parameter for:

- Gasovi (use natural main gas or balanced balloon gas). The first option is to get into the best. Do not depend on the possibility of connecting the system to the main gas pipeline;

- Hard-fired (the most universal and often stagnant, which can also be used for anthracite, wood, wood, pellets, alarm smitty, in the way of processing of some types of s / g products) is too thin.

- Proceed with light oil (fuel oil, diesel oil, thin oil).

Basic steps for the installation of a steam system

The robots are repaired from the development of the detailed project for the project, the selection of the necessary model of the boiler and the other materials and possessions.

Dal, for consumption, at the planned installation of opaluvial attachments, the preparation of the surface must be performed in advance.

The boiler will be installed according to all the rules for connecting to the systems: burning, supplying condensate, burning too much.

Vstanovlyuyutsya opaluvalnі attach, vikonutsya laying the pipes of the system scorching, mounted regulating and locked fittings, valves, pump just.

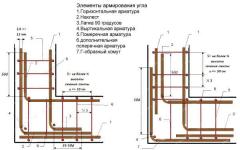

Victory of stainless steel flanges during installation of systems and firing

All elements of the system, including parts of the pipeline and annexes, which can be connected beforehand (boiler, pump, control and monitoring) are connected to the flanges. At the crossroads of a large number of vapors they weld or screw them to the ends, as they plan to do it.

Behind the design flange is a flat-shaped disc, prepared from steel of high quality, along the perimeter of which a number of openings are prepared, one way apart, through which one can see the frames from the bolt pins. In addition to the vasne pipelines, the flanges are widely zasosovyvayutsya for the installation of large capacities and equipment.

It is important to remember that all flanges from steel are supplied and supplied with a set (2 pieces).

The virobi have apparently recommended themselves in the minds of significant high temperatures, on reports with advanced logos, etc.

To reject big