The slab foundation is used to find and vibrate when the buildings are on unstable and susceptible soils. This type of inflow is minimal to the ground and will ensure a steady flow of all cars to the ground. The pouring technology itself is simple, the main emphasis is on the development of the parameters of the slab, and the very: glibin of the slab, the height of the cushion, the brand and the concrete for the concrete, the reinforcement rebar, use in the insulation. The range varies from 15 to 35 cm, as the size of the size changes, then there are some basic options.

It is a concrete monolith with two rows of mesh with reinforcement, which is spread over the rammed food cushion, in especially folding vipad - strengthening with the ribs of the stiffness from the bottom. The value of vitrates for the first time to lay down on the step of dimming from the ground: on stable soils it is practically practical to compare with the earth and in the least investment and hardening. On plyut soils, if necessary, the organization of a large space on the slab foundation is up to 1/3 of the budget, so the laying is carried out below the level of freezing.

To comply with the norms, the ball of the armored mesh should be spaced at least 5 cm from the edge of the plate, 7 - between itself, the minimum break of the armature is 12 cm. It is not possible to change the position, the exact parameters of the monolithic foundation are not possible. Otrimannya vnіvnuyuyut s recommended for urahuvannya vagi budіvlі and geological minds dіlyanka:

The slabs for the wooden booth should be laid down from the surface, with good drying of the materials, the pitoma does not change 600 kg / m 3, which is 2.5-3 less, lower than the center. Yak inheritance recommended warehouse value 30 cm.

The aftermath of the development of the company

Prior to the final tribute, it is necessary to carry out: all vars for installation, including snigovs, a vise on the ground for a given type of foundation (pre-size, lay in the type of soil), area with equipment. It’s a matter of self-monolithic plateau to ignore the producers of food on pillows. The main steps for the development of the system:

- Analysis of soil and determination of the optimal vise for the foundation.

- Rozrahunok Masi Sporud. Pidsumovutsya va stin (including processing and heat insulation), re-grits, covering constructions, furniture, snig on dakha charge.

- Viznachennya pet navantazhennya on the ground by way of the road to the booth on the area and according to the normative values. Otrimana growth is multiplied on the size of the slab foundation, the number of different types of the necessary mass.

- The optimal size of the lath (the ratio of the front value to the concrete volume) and the level of the monolith.

- Rounded to the nearest value, multiples of 5 (not important in a bik).

- Pererakhunok massi monolithic foundation and according to the recommended, the increase is not guilty of perevischuvati ± 25%.

By the step of the step є the value of the optimal layer of laying and the thickness of the cushion with crushed stone and sip, and the factor is without the need to lie down in the type of soil. The minimum height of the trench is 60 cm, ale such a laying is permissible only on stable soils. In all slabs, the slab foundation is displaced 60 cm below the frozen ground. Tovshchina zasipki to lay down from the carriage with the equipment, the minimum is to become:

- For the garage - 25 cm.

- Light board structures - 15 cm.

- The foundation for a booth from a bar is 25-30 cm.

- For baking sack and concrete - 50 cm (s ni 20 - crushed stone, 30 - sack).

The whole ball will secure the uniformity of the rosette of the carriage, on folding soils it will increase by 5 cm as a minimum.

The stage of building a monolithic foundation by crocs

The robots will repair the analysis of the soil and the placement of the sleep itself and the pillows in front of it, because of which there is a need for a number of budget materials. When building a monolithic plate, it is recommended to use the following schemes:

1. Razmіka dilyanka and earthly robots.

2. Laying of geotextile cloth along the bottom and perimeter of the walls of the vicopan pit.

3. Distribution of drainage water. Non-viscous stage, vibrate at high level of groundwater. Along the bottom of the foundation pit, they cut small trenches, close them with the same geotextile, on top of which plastic pipes are laid with openings. For someone to boil with crushed stone and cover the sieve with one ball. Recommended scheme of pipes rostashuvannya - across the maybutny monolithic plate.

4. Organizaciya pillows, peeling and ramming rubble (on especially foldable soils - seeps with bitum), when the operation is repeated from the start, in order to lighten the process of crushing, it can be slightly snarled. At the whole stage, it is not easy to get involved in technology, it is not easy to reach the required level of competence without possession.

An important nuance: to pick up a song only from the great fractions, when you change the pillow, 10 cm will be rammed around.

5. Laying of the communal system is backward in the folded circuit (if necessary). The whole stage is carried out one hour in advance, the water pipes are piped and the pipes are raised on top of the crushed stone. Sverdlinnya monolithic foundation plate in order to get caught up in gross deterioration of technology, think carefully whether dibnitsi.

6. We wash the bottom of the foundation pit with concrete. Another optional step, ale of recommended steps, which is used to get rid of the risk of overheating or dry soil. Tovshchina fill the ball - in the space of 10 cm.

7. Installation of formwork structures, revision of the design and visualization of the rim.

8. The flooring of a roll-type hydro-insulator with an elastic band around the edges is close to 1 m.

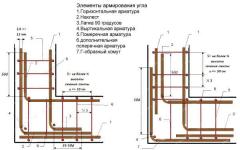

10. Armor - ligation of the golden rods with a minimum overhang of 12 mm behind the additional plastic clamps or a dart with an interval of 20 to 30 cm. At all stages, it is important not to insulate the heat-insulating material (if it is evident), but rather to hydro-insulation, that is, by twisting the special plastic materials.

11. Pouring concrete. The tsey stage is carried out in one day, with a great foundation of the big sense to replace the ready razchin. It is allowed to independently prepare concrete with a mark of quality not lower than M300, or an allowable interruption in the process does not change for 12 years. Concrete is poured, rammed and rammed randomly around the entire perimeter of the monolithic slab. Zapovnennya okremimy dilyanki to produce up to the approval of tremors, the whole factor is one more proof of the reproach of the factory. The concrete is poured with clay vibrators, in extreme fall - I will hand it over, when the surface is smoothed, covered with slats and covered with polyethylene plastic.

12. A knight of a monolithic foundation - not less than 4 times, with a viscous peep behind the surface (cut by water) for the first 7-10 days.

13. Construction of the formwork, hydraulic insulation of the wall plates, and itself - lifting and mounting to the walls of the earlier roll-up materials.

The technology has been assigned to the foundation of a significant investment and labor-nitrate, it is important to think that all stench will be lost when you choose the wrong plate or gibini and zalyagannya. Such a step, as an analysis of the soil, the development of the parameters in the submission and without the middle concrete is unambiguously varied to do it. Dana pokrokova іnstruktsіya pіdhodit for Institution ploskoї monolіtnoї zalіzobetonnoї plate, the neobhіdnostі gasket edges zhorstkostі protses uskladnyuєtsya:. Gotuyutsya spetsіalnі transheї uzdovzh nesuchih stіn of Krokom not less than 3 m Ale їh tochnі rozmіri i іnterval viznachaє convertible іnzhenerny rozrahunok in the privacy budіvnitstvі Tsey varіant vikoristovuєtsya rіdko ...