The understanding of the "formwork" is based on an additional auxiliary construction, intended for the construction of important elements of construction. The metal formwork stagnates, as a rule, when plastering the concrete buildings with improved operational characteristics. Appointing the formwork of the clearing in the secured above-ground hydro-isolation to the foundation, the clearing of the concrete ball of the wall from the erasure and early ruining.

The order of the foundations and supports awake, in the row of vypadks, the formwork is vicious when installing non-loose elements of the aboveground part of the awakening: columns, perekrittiv and stin. By the initial power of any formwork є easy dismantling without breaking the concrete ball and changing it from the stage to the stage when using floating technologies.

To prevent adhesion and hardening of concrete madness on formwork sheets, it is recommended to use special bricks and fix them in special mastic warehouses.

Special features for the installation of formwork systems

The current vyroblyayut majesty the number of types of formwork systems from metal, so that one of one kind of railing attachments and special features of the installation are made. Another name for such technologies is inventory formwork.

Metal formwork to climb from the surrounding shields

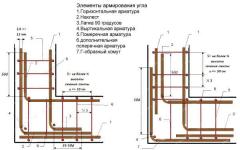

Metal formwork to climb from the surrounding shields The optimal type of vibration in the deposit is due to the designation and design characteristics of the elements being built: foundation, wall, cross, etc. As a rule, the set of formwork includes steps:

- a number of shields;

- krіpilny pristosuvannya;

- Tighten and supplement annexes.

The ready-made kit is guilty of allowing the production of sporium in the establishment of terms.

On a leather formwork kit, a vyrobnik vipisu technical passport, which shows the designation of the kit, the main authorities and the specifics of warehouse parts. The relevance of such sets is growing rapidly with bagatorazny vikorystanny formwork in a large-scale business.

For storage of formwork attachments with regular installation and dismantling, it will not be possible to create a special maidan, it will be removed in a distant space from which elements are built.

The procedure for installing the formwork system includes the following operations:

- sinking and displacement of the formwork panel before installation;

- Timchasova fixing of a warehouse element;

- vivirka of horizontals and verticals of the surface;

- the residual fixation behind the auxiliary attachments and the fixing of the auxiliary annexes.

The procedure for dismantling is based on respect for the return of the message. In case of significant cyclicity, it is recommended to carry out a round-trip before the installation, cleaning the working areas from the adhered timber, partial repairs and mastication.

Reversals of metal formwork

Metal formwork can be easily dismantled

Metal formwork can be easily dismantled

The metal formwork for the foundation is characterized by the onset of the initial transitions:

- Possibility of preparing ideally equal surfaces of the walls;

- simplicity of robots (a short term for dismantling and quick assembly of the formwork from the metal, according to the previous milling of sheets and the preparation of warehouse parts in the factory minds);

- zhorstk_st is necessary (under the pouring grip of the metal shield does not viginate, it takes the ideal form to oblast the parts of the equipment);

- Visoka turnover or capacity of a victorious (the term of service of metal sheets of enclosures deprives it of such power, as in the case of metal, it can be manifested only if the end of an hour of regular filing of such material).

If necessary, a one-time registration of formwork sheets, it is recommended to speed up the services of rent metal virobes. At the same time, the maximum yield to be built on top of the foundation will be reached without a hundred penny infusions.

Yak і be-a kind of wake-up material, metal is a hundred and a half short-lived - є with a watchful syruvina. Unimportant at the time, the popularity of metal formwork is growing steadily because of the fact that the performances minus are more than compensated for by the passages of the given material.

Types of formwork structures

The girder formwork is stored from shields, heavy and pied

The girder formwork is stored from shields, heavy and pied

At the present moment, the type of formwork for the foundation, where to avenge metal virobi, is widely used in case of large-scale construction. Naybіlsh expands from them є nastenі vidi:

- beam-transom;

- large-shield;

- dibno-shield;

- formwork-lining.

The choice of the optimal type of formwork system is rich in nutrition, and there are many reasons to be based on the quality of technology and rules for the installation of structures, as well as the technical and financial capabilities of the forgetful.

Beam-transom view

Beam formwork is often used to fill columns

Beam formwork is often used to fill columns In a large number of views, the type of formwork is stagnant when monolithic or random monolithic structures are prepared. On the other hand, a cross of surfaces, inconspicuous walls, columns, elements and foundations are formed.

The stagnation of the girder-girder of the technology is supported by the possibility of opening the ideal concrete surface in a straight line, as well as in a singular form, with the necessary curvature.

At the same time, the power of the formwork design has been made possible to rob the people of the colony of small spills and areas, to use the technology that is indispensable when working out, as it is clear to the aristocratic architects.

Before the crossing, the following should be brought to the fore:

- the lightness of the design is reconciled;

- ease of installation of stin and the ability to combine storage elements;

- visoka shvidk_st dismantling;

- Possibility of bagatorazovaya zasosuvannya without carrying out intermediate cleaning procedures;

- Possibility of victorian in combination with other formwork technologies.

Large-shield type

The formwork system for the foundations of the presented type includes a loose and non-solid profile from aluminum and steel to its warehouse. Yak material for formwork panels is framed by laminated wood (plywood) with sheet thickness up to 18 mm.

Large-panel formwork vikoristovuyutsya for the construction of walls and perekrittiv

Large-panel formwork vikoristovuyutsya for the construction of walls and perekrittiv The design is ready to climb out of the wooden shields, so that it can be found by being a kut with oneself behind the help of hinge elements. Allowed navantazhennya - 8 000 kg / sq. M. The creation and distribution of the shuttering sheets is followed by additional locks in the form of a wedge. The names of the attachment elements are fixed in a special zholobi, roztasovany from the inner side of the shields, udovzh maybutnіh stin. Every year I have recruited a number of shields to arm and tighten with a special stud and a set of nuts.

The shape of the panel elements is interchangeable, as well as the possibility of installing the yak in a vertical or horizontal position, which will ensure a wide functionality of such a formwork system.

Z perevag large-panel formwork slid vidіliti:

- technological rigidity;

- aside from the speed of editing;

- the ease of covering the walls and plumbing fixtures.

Disadvantages of the presented type:

- the problematic nature of the distribution of the concrete warehouse;

- the number of special techniques is significant.

Its own large-scale panel formwork has been built up with the construction of large-scale housing stock and the construction of large-scale construction.

Dribno-shield type

The particularity of the named technology is dependent on the large-panel type of pole in the dimensions of the complementary virobes. The main advantage of the timber-panel timber construction is the ability of the stem of any other architectural form for pouring concrete.

Along with the lightness and small dimensions of the warehouse parts, it is possible to install with your own hands without the need for special equipment, both in the vertical and in the horizontal direction, but at the same time, the budget and the allowance for the construction of the elements are practical, be it practical.

Marvel at the video, how the installation of small-sized type of formwork systems is being considered.

Likewise, in the previous types, all of the completing are prepared in the factory minds, so that they will take away the high number of other sewing machines. At the connection with the cim of its own construction, an inventory formwork is presented in a private building, especially when the foundation is built.

visnovok

Inventory formwork is one of the most effective types of formwork systems, which allows for a high quality and in the smallest terms to create a necessary structural element: a foundation is absent. In the course of the installation of the presented type, it is necessary to emphasize the accuracy of the folding. Proceeding to concrete, with especial respect to reconsider the need for locks and contacts in existing annexes.

Competent attention to the instructions, we will propose to you and to the normative documents in the stand of the guarantor of the high-quality function to be built with the equipment.